聚合物立式棒状柱塞挤出机PFLB20直径4mm-20mm

产品详情:

一、PTFE(UHMWPE)柱塞棒材挤出机PFB20的特性

通过持续改进,使设备更智能、更稳定、更高效。

设备采用PLC系统控制,操作自动化,操作简单。

设备设计多样,可满足用户的不同需求,并为客户定制。

设备长时间稳定运行,噪音较低。并通过在压力维护期间节省电力和能源来降低成本。

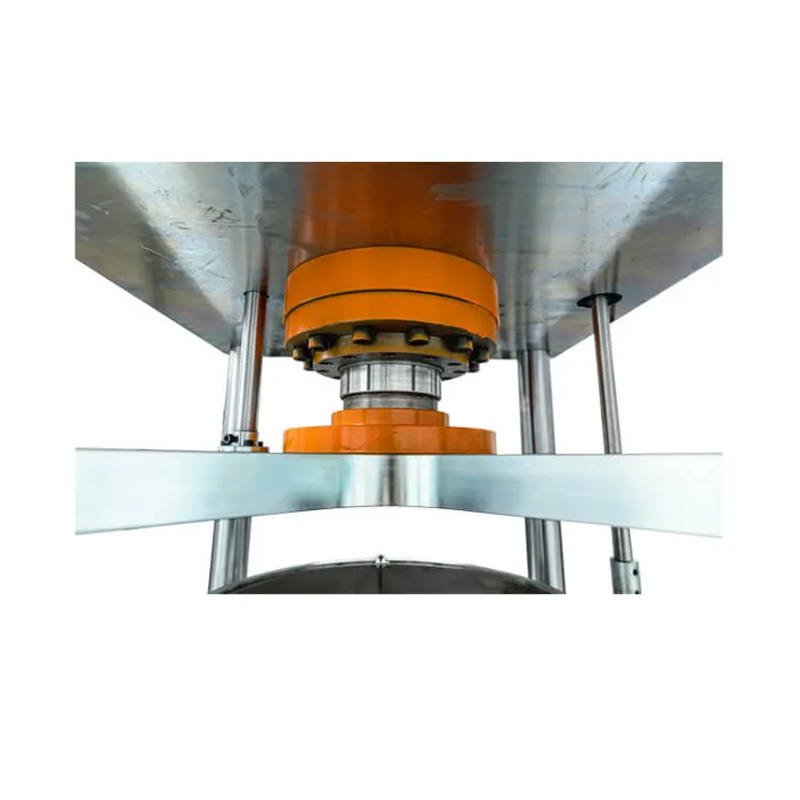

设备和模具均采用特殊工艺制造,耐腐蚀,经久耐用,使用寿命长。

设备设计简单,占用空间小。

挤出产品在密度和抗拉强度方面具有优越的性能。

配备自动上料系统,灌装一桶50-80公斤,自动上料系统可保证4-8小时运行,很大程度上节省人工成本。

聚四氟乙烯柱塞棒挤出机可以连续推动棒材,棒材可以根据要求进行切割。

提供完整的模具系统,其中包括全套相应的配件、加热烧结系统、冷却系统、温度控制器、支架等。

立棒挤出机从上到下挤出。该设备可以放置在二楼或平台上。

2.设备运行环境要求

要求场地地面平整,场地荷载不小于设计要求。

操作平台需要干净的空间来减少灰尘的进入。车间内最好有通风管道,以利于通风。

工业电源标准380V 50Hz 3P,电压可根据用户需求定制。

厂区配备有配电柜、压缩空气等配套设备。

设备需要配备冷却系统。两个水桶/水箱可以与冷却泵一起使用,以回收水资源。

植物的室温应不超过28°C。

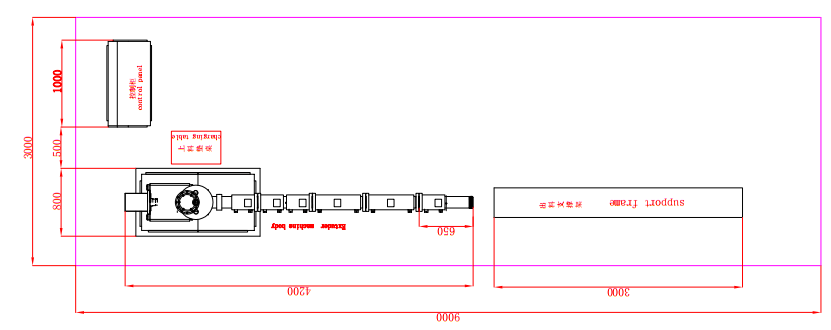

立式挤出设备从上到下挤出。设备安装在空间高度约2.8米的平台或地板上。需要考虑设备纵向的有效距离,并且必须保证设备的固定圆孔下有足够的高度,以满足挤塑聚四氟乙烯棒的长度要求。

水平挤出设备需要考虑设备水平方向上的有效距离,并且必须保证聚四氟乙烯棒的长度。该设备包括一个模具长度为4-7米(不包括挤压成品棒的长度),宽度为1.2米,高度为1.8米。

三、设备参数

| 机器型号 | PFLB20型 | PFB80型 | PFB150型 |

| 过程 | 立式挤出 | 水平挤出 | |

| 功率KW(电动机) | 14 | 24 | 33 |

| 杆径(mm) | 4-20 | 25-80 | 80-150 (200 ) |

| 挤压棒长度 | 继续以无限长度挤出 | ||

| 控制器 | PLC+触摸屏 | PLC+触摸屏 | PLC+触摸屏 |

| 产量(Kg/h) | 7+ | 8+ | 10+ |

| 电压/ PH/Hz | 380V 50赫兹 3P | 380V 50赫兹 3P | 380V 50赫兹 3P |

| 耗电量(KW/h) | 2+ | 2.5+ | 3+ |

| 温度区 | 3-5 | 4-8 | 8-12 |

| 机器重量(Kg) | 930 | 960 | 1220 |

| 机器高度 (mm) | 2150 | 1800 | 1900 |

| 机器占地面积 (m2) | 3.5 | 7 | 10 |

| 模具 | 模具尺寸根据客户规格定制。成套模具包括模体、挤出头、连接法兰、高温加热环成套、传感器成套、冷却水套系统、高温连接线、模具和产品支架。表面光洁度经过特殊处理,光滑、耐用且耐腐蚀。保温棉厚度大于5mm,加热厚度大于10mm。 | ||

4. Equipment Installation and Mold Installation Diagram

5. Equipment And mold Maintenance

Regularly check the height, cleanliness and temperature of the hydraulic oil.

It is recommended to replace the hydraulic oil every six months.

Replaced worn seals timely.

The mold should be cleaned and maintained in time, and the surface should be coated with a thin layer of protective oil.

Carefully handle the temperature sensor of the heating coil, and store it properly.

6. Accessories And Spare Parts Description

The equipment is composed of main machine, a hydraulic station, a control cabinet, an automatic feeder, holders, heating cavities, molds and other accessories. Equipment necessary accessories are sent to customers with the equipment.

The list of necessary accessories for the equipment is sent to the user with the equipment.

When the user purchases our company’s equipment, in addition to the necessary accessories, we will provide the necessary spare parts to the user to replace and repair the equipment. Spare parts are standard parts and can be purchased in the local market.

7.Process Guidance

Due to the special technology of the equipment, customers can go to the factory to learn about the installation, commissioning, operation, mold change, maintenance, process guidance of the equipment for free before delivery.

If you are unable to come to our company to study due to inconveniences such as distance, personnel, time, we can arrange for engineers to come to guide the installation, commissioning, operation, mold replacement, maintenance, and process guidance of the equipment under the agreement of the other party.

We can also conduct remote guidance. Users can choose other methods such as telephone, video, email, etc. to learn about equipment installation, commissioning, operation, mold change, maintenance, process guidance, etc.of the equipment.

8.After Sales Service

From the date of receiving the machine, the warranty period of all machine accessories is one year. We provide free maintenance guidance service during the warranty period.

If there is any problem with the accessories outside the warranty period, please contact us in time to explain the problem, and we will provide follow-up resolution within 24 hours.

If we have a local distributor, we can contact the local distributor for cooperation.

All questions about the equipment can be consulted to us by mail, video, telephone, etc.

9.PTFE Rod Line Automatic Feeding Equipment

Vacuum automatic feeding, including compressed air reverse blowing system, start feeding system, wash hose, suction gun, vacuum generator, PCB controller,throughput 30-300 kg/h, diameter 150mm and height 600mm, set automatic feeding time and discharging time, powder flow is controllable, all stainless steel production, intelligent control. The mixing barrel is 600mm in diameter and 700mm in height, with a 2.2kw reduction motor, a stirring speed of 15-25 turns/min, 8-10mm thick bottom plate, and a feeding capacity of 75-90kg.

SKVQC-10 Configuration List:

| Name | No. | Brand/Manufacturer | |

| Vacuum generator | 1pcs | China | |

| 316L stainless steel filter | 4pcs | China | |

| Vacuum hopper(304 stainless steel) | 1set | Suko | |

| Compressed air reverse blowing system | Backflush valve | 1set | New Zealand |

| Pneumatic component | AirTAC | ||

| Air emptying system | 1set | China | |

| Control system | Pc board | 1set | Suko |

| Switching power supply | 1pcs | China | |

| Solenoid valve | 1pcs | AirTAC | |

| Suction hose(Φ25)food-grade steel wire reinforced hose | 3M | Germany | |

| Stainless steel suck nozzle(Φ25) | 1pcs | L 350mm | |

| Stainless steel barrel | 1pcs | OD600mm;H700mm | |

| Gear Motor | 1pcs | 1.5KW 15-20r/m | |

Technical Parameters:

| Model | Compressed air consumption | Air pressure |

| SKVQC-10 | 180L/min | 0.4-0.6MPa |